Multiple Choice

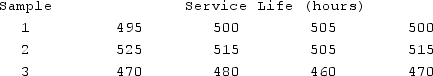

A design engineer wants to construct a sample mean chart for controlling the service life of a halogen headlamp his company produces. He knows from numerous previous samples that this service life is normally distributed with a mean of 500 hours and a standard deviation of 20 hours. On three recent production batches, he tested service life on random samples of four headlamps, with these results

If he uses upper and lower control limits of 520 and 480 hours, on what sample(s) (if any) does service life appear to be out of control?

A) sample 1

B) sample 2

C) sample 3

D) both samples 2 and 3

E) all samples are in control

Correct Answer:

Verified

Correct Answer:

Verified

Q64: The process capability index (C<sub>pk</sub>)may mislead if<br>(I)the

Q65: Which of the following is not a

Q66: The following data occurs chronologically from left

Q67: The approaches to quality assurance are<br>A)process inspection,

Q68: Process capability compares process variability to the

Q70: The probability of concluding that assignable variation

Q71: Larger samples will require wider x-bar control

Q72: The chair of the operations management department

Q73: A p-chart would be used to monitor<br>A)average

Q74: The variation of a sampling distribution isless