Essay

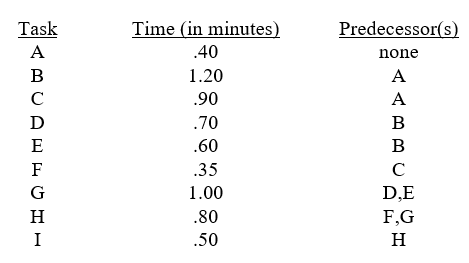

A company is setting up an assembly line to produce cellular telephones.They intend to use line balancing with the longest-task-time heuristic.They know the demand per hour is 40 phones and the productive time per hour is 54 minutes.Displayed below is the data they have collected regarding task precedence and times.

a.What is the cycle time?

b.What is the theoretical minimum number of workstations?

c.What tasks are assigned to the first workstation?

d.How many workstations are needed for the entire line?

e.What is the assembly-line efficiency?

Correct Answer:

Verified

a.Cycle time = 54 min per hour/40 units ...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q5: Explain the role of ergonomics in job

Q19: Describe approaches used for process layout design.

Q23: _ set their own goals and inspect

Q25: An assembly line with 28 operations is

Q26: All of the following are common objectives

Q27: Discuss the advantages and disadvantages of utilizing

Q30: The Florida Appliance Company is installing an

Q32: CRAFT is a process layout technique that

Q45: Facility layout is not only concerned with

Q74: An assembly line is a type of