Essay

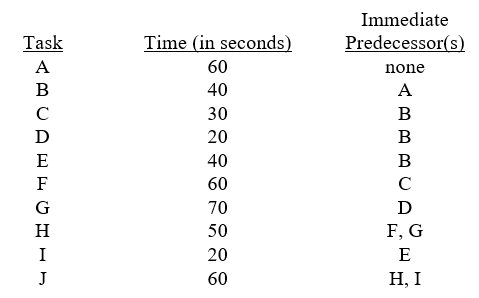

The Florida Appliance Company is installing an assembly line to produce vacuum cleaners, and you, as an operations manager, are responsible for balancing the line.The tasks to be performed are listed, along with their times and immediate predecessors. The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

Correct Answer:

Verified

a.Cycle time: CT = A/R = 960/480 = 2 min...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q5: Explain the role of ergonomics in job

Q19: Describe approaches used for process layout design.

Q21: Explain the sociotechnical approach to job design

Q25: An assembly line with 28 operations is

Q26: All of the following are common objectives

Q27: Discuss the advantages and disadvantages of utilizing

Q28: A company is setting up an assembly

Q32: CRAFT is a process layout technique that

Q45: Facility layout is not only concerned with

Q69: Discuss four reasons for conducting a facility