Essay

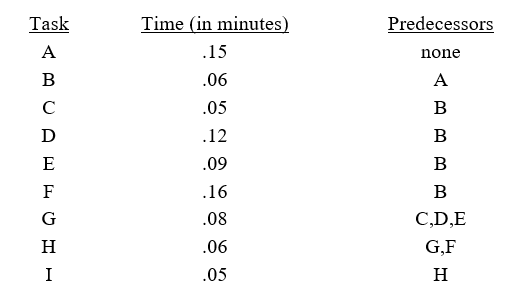

The nine tasks necessary to assemble a vacuum cleaner are listed below.The time to perform each task and the tasks that must immediately precede are also listed.300 vacuums are needed per hour and 50 minutes per hour are productive.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the production line.

d.Compute the efficiency of the assembly line.

Correct Answer:

Verified

a.Cycle time = 50/300 = .167 minutes per...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q48: Workers in cellular layouts generally have greater

Q66: Virtual teams are empowered work teams that

Q67: Differentiate between a "flow blocking delay" and

Q70: Which is true for product layout?<br>A)Very flexible<br>B)Lower

Q71: An assembly line with 28 activities is

Q73: Because of precedence relationships, assembly-line efficiencies will

Q74: List the many questions that must be

Q75: A small electronics company assembles power supplies

Q77: Assembly line balancing<br>A)Is a one-time activity.<br>B)Tries to

Q78: Assembly-line balancing problems involving many distinct products