Multiple Choice

Table 6.2

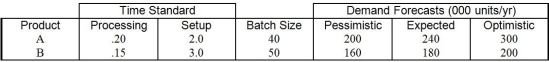

High Tech,Inc.is producing two types of products: A and B.Both are produced at the same sawing operation.Because of demand uncertainties,the operations manager obtained three demand forecasts (pessimistic,expected,and optimistic) .The demand forecasts,batch sizes (units/batch) ,processing times (hr/unit) ,and setup times (hr/batch) follow.  The sawing machines operate on two 8-hour shifts,5 days per week,and 50 weeks per year.The manager wants to maintain a 10 percent capacity cushion.

The sawing machines operate on two 8-hour shifts,5 days per week,and 50 weeks per year.The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 6.2,what is the minimum number of machines needed (assuming no reliance on short-term options) ?

A) fewer than or equal to 22

B) more than 22 but fewer than or equal to 25

C) more than 25 but fewer than or equal to 28

D) more than 28

Correct Answer:

Verified

Correct Answer:

Verified

Q13: The lock box department at Bank 21

Q24: Figure 6.1 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Figure 6.1

Q25: Table 6.5<br>The T.H.King Company has introduced a

Q27: Table 6.4<br>Mr.Lee is considering a capacity expansion

Q28: Table 6.5<br>The T.H.King Company has introduced a

Q31: Table 6.6<br>Burdell Labs is a diagnostic laboratory

Q32: Expand Test Center A at the end

Q34: Innovative Inc.is experiencing a boom for the

Q76: What is a waiting line model, and

Q119: An expansionist capacity strategy:<br>A) lags behind demand.<br>B)