Multiple Choice

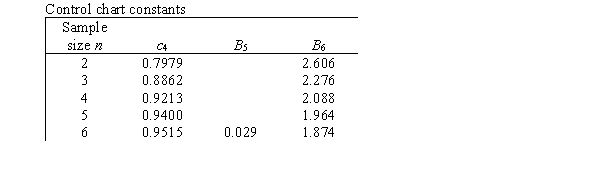

Piston rings for an automotive engine are produced by a forging process.We monitor the inside diameter of the rings manufactured by this process using an  and an s control chart.Samples of size 4 are taken at regular intervals,and the sample means and standard deviations are computed and plotted on the charts in time order.The overall mean of the sample means is 73.812 millimeters,and the mean of the sample standard deviations is 0.022 millimeters.The control chart constants are (partially) reproduced below.

and an s control chart.Samples of size 4 are taken at regular intervals,and the sample means and standard deviations are computed and plotted on the charts in time order.The overall mean of the sample means is 73.812 millimeters,and the mean of the sample standard deviations is 0.022 millimeters.The control chart constants are (partially) reproduced below.  What value would we use for the center line of the

What value would we use for the center line of the  chart?

chart?

A) 68.003 millimeters

B) 73.790 millimeters

C) 73.812 millimeters

D) 154.119 millimeters

Correct Answer:

Verified

Correct Answer:

Verified

Q9: When a process variable is Normally distributed,there

Q10: Parts manufactured by an injection molding process

Q11: The data below represent the means from

Q12: Parts manufactured by an injection molding process

Q13: Which of the following statements about special

Q15: Statistical stability means there is no variation

Q16: What do control limits show?<br>A)The exact value

Q17: Which rule will typically signal an out-of-control

Q18: In an electronics company that produces transistors,1000

Q19: Suppose you are the owner of a