Essay

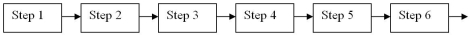

Consider the process shown that is trying to produce to meet a market demand of 500 units per week.  Step 1: Material release schedule

Step 1: Material release schedule

Step 2: Drilling (capacity is 500 units/week)Step 3: Tapping (capacity is 450 units/week)Step 4: Grinding (capacity is 600 units/week)Step 5: Coating (capacity is 400 units/week)Step 6: Inspection (capacity is 1000 units/week)a.Where should buffers be placed?

b.Which resource is the drum?

c.Where should the rope be placed?

d.Which resource is the bottleneck?

e.Which resource is the CCR?

Correct Answer:

Verified

a.A constraint buffer should be placed b...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q35: A bottleneck process has the lowest capacity

Q40: A(n) _ line is a product line

Q51: The fourth step in Theory of Constraints

Q78: Paced lines require that inventory storage areas

Q133: What are five of the seven key

Q152: Table 7.8<br>King Supply makes four different types

Q155: The production of a particular product consists

Q156: Table 7.5<br>A company makes four products that

Q158: Table 7.2 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Table 7.2

Q159: Describe three ways that line balancing and