Multiple Choice

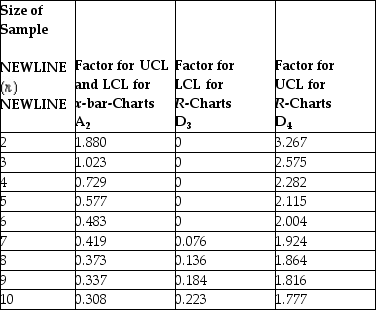

Table 5.1

Factors for Calculating Three-Sigma Limits for the  Chart and R-Chart

Chart and R-Chart

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

-A milling operation has historically produced an average thickness of 0.005 inch with an average range of 0.0015 inch.Currently,the first three items from each batch of 20 are inspected.Use Table 5.1.What is the value of the lower control limit for the x-bar chart?

A) less than or equal to 0.00100

B) greater than 0.00100 but less than or equal to 0.00299

C) greater than 0.00299 but less than or equal to 0.00499

D) greater than 0.00499

Correct Answer:

Verified

Correct Answer:

Verified

Q14: In acceptance sampling, the proportion defective that

Q31: Table 5.2 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Table 5.2

Q33: Samples of size four were taken from

Q34: Table 5.2 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Table 5.2

Q53: What are any three dimensions of quality

Q80: What are the key components of the

Q129: A firm's internal program in employee involvement

Q145: On a control chart, a type I

Q179: The advantage of variable measurements is that

Q192: In SPC, the distribution of sample means:<br>A)