Multiple Choice

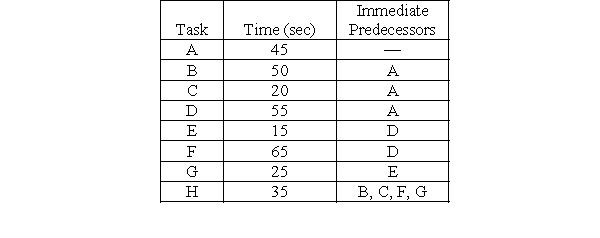

The process design team at a contract manufacturer in Thailand has broken an assembly process into 8 basic steps, each with a required time and predecessor, as shown in the table. There are 7.5 productive hours available in a day, and the manufacturer wishes to produce 400 units.

-The managers decide to balance the line by assigning tasks to workstations to fill up as much task time as possible. Break ties by assigning the longest task first. What task(s) should be assigned at the third workstation?

A) D

B) B, E

C) F

D) C, E, and G

E) Need more information to answer the question

Correct Answer:

Verified

Correct Answer:

Verified

Q56: Use the Cluster-first-route-second heuristic for two trucks

Q57: Assume a facility is open 8 hours

Q58: Use the Clark and Wright savings heuristic

Q59: Assume a facility is open 8 hours

Q60: Assuming that the customers are ranked in

Q62: A tier-two supplier needs to produce 300

Q63: Assuming that the customers are ranked

Q64: ADAMS Electricals has decided to analyze the

Q65: For the Buehler Bakery, the desired output

Q66: The following is a sketch of process-focused